AG-EPC 32 is the new generation CNC Promax. The performances are ideal for Middle/high-level professional machines. The type of controlled axes allows a wide choice of engines, with the possibility of being able to use mixed solutions. This uses ISOUS for GCODE PC application. The CPU integrates 1 EHTHERNET, 1 ETHERCAT CoE, 2 RS232 serial ports (1 – 485), 1 CanOpen, 8 Analog Inputs 12 Bit, 2 Analog outputs 0-10V. With appropriate expansions, you can integrate up to 80 digital inputs, 70 outputs, 6 analog outputs and 6 channels of 500 Khz encoder. The PC connection is via ETHERNET up to 100 Mb. There is no memory limit with regard to the Part Program, since this uses the PC’s RAM.

Video

|

- CanOpen – 6 Axes

- Ethercat – 6 Axes

- Pulse/Dir – 6 Axes

- +/-10V – 6 Axes

|

|

Position Loop on External Encoder

When is used FieldBus CanOpen, or Pulse/Dir, AC-EPC-32 can close the position loop in external encoder. This allows to increase the machine precision

|

|

R.T.C.P. (Rotate Tool Center Point)

This function is specially designed for 4/5 axes machines with rotating/tilting spindle head. It’s designed to continuously guarantee the perfect contact between the tool and the workpiece surface, during A&C axes movements. This function is widely used in woodworking machines.

|

|

Work Plan Mapping

This special function, allow to map the work area, using a sensor.

In this way we can automatically adjust the Z position, independently by path interpolation, correcting the non-planarity zones of the work plan.

|

|

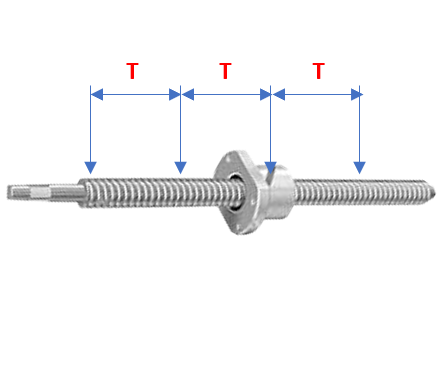

Axis Mapping

Capability of mapping in internal memory all Axes. This allows to correct the position in REAL TIME.

|

|

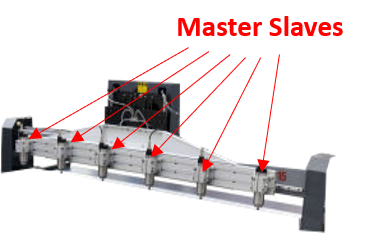

Gantry

From machine parameter is possible to set one or more Gantry Axes connetcted to Master.

|

|

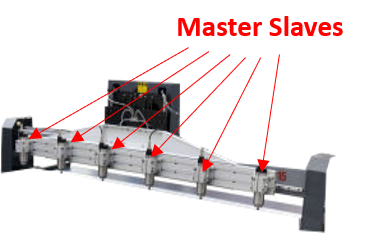

Master Slave Axes

NgWarp can control by Gcode instruction one or more Master/Slave Axes. Is possible manage up to 4 groups of Master/Slaves Axes.

The max number of Slaves for single master is 8.

|

Características técnicas

Axes

| Interpolated CanOpen |

6 |

| Positioned CanOpen |

16 |

| Interpolated Pulse/Dir |

6 – 500 Khz Clock |

| Positioned Step/Dir |

6 – 500 Khz Clock |

| Interpolated Ethercat |

6 |

| Positioned Ethercat |

16 |

| Rotative |

6 |

| Axes Resolution |

Programmable – min. 0.000001 mm |

| Feed Resolution |

Programmable – min. 0.001 mm/min |

| Tangential Axes |

With special interpolation |

| Gantry |

On All Axes |

| Master/Slave |

By Gcode G108 |

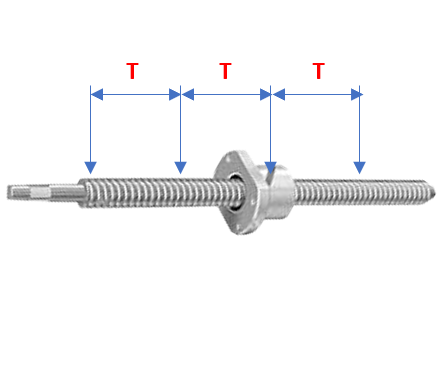

| BackLash |

On All Axes |

| R.T.C.P. |

None |

Interpolation

| Types |

Linear, Circular, Helical, HSM,3D |

| 3D |

With calculation automatic 3D threshold edge |

| Contour Plan |

On all Pair of Axes |

Special Functions

| Recovery Processing |

From Line Number, Tn, from Marker |

| Retrace |

From JOG Axes and resume from any point |

PLC I/O

| Digital Inputs |

80 – PNP 24 Vdc |

| Digital Outputs |

70 – PNP 24 Vdc with protection |

| Analog Inputs |

8 – 12 bit |

| Analog Outputs |

6 – +/- 10V (Ag-SX) 2 . 0 10V on Base |

| Fast Inputs |

12 – Interrupt mode |

| Relè Outputs |

6 – 1A |

| Encoder Inputs |

6 – Line Drive 500 Khz |

Ports

| CanOpen |

1 – Master/Slave |

| Ethercat |

1 – CoE |

| Serial |

2 – RS232 1/RS485 |

| Ethernet |

1 – 10/100 Mb |

| USB |

1 – Programming |

Other

| Handwheel |

On All Axes |

| Axes Sample |

500us Min. |